产品

PRODUCT

ALD

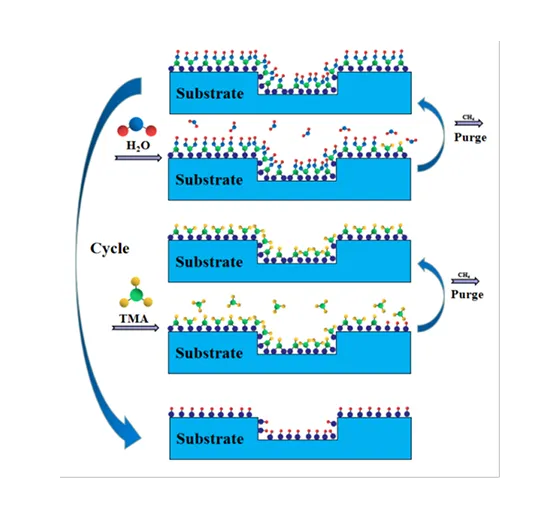

ALD (atomic layer deposition) is a specialized chemical vapor deposition technique that deposit thin films by alternately pulsing gaseous precursors onto the substrate in the reaction chamber, where they chemically adsorb and react on the substrate surface.

The classic reaction between TMA and H2O to form aluminum Al2O3:

Half-reaction a: -OH∗ + Al(CH3)3(g ) → - O - Al(CH3)2∗ + CH4(g)

Half-reaction b: - O - Al(CH3)2 + 2H2O(g) → - O - Al(OH)2∗ + 2CH4(g)

Reaction: 2Al(CH3)3 + 3H2O → Al2O3 + 6CH4

Atomic Layer Deposition (ALD), as an advanced chemical vapor coating technology, enables conformal coating on irregular surfaces of substrate materials with the following characteristics::

▪ Linear and controllable coating thickness: 0.1–0.2 nm/cycle

▪ Uniform and dense coating layers

▪ Low-temperature growth (some films can be deposited at room temperature)

▪ Growth of multi-component layered structures

▪ Diverse coating material options

Related products

Products category

For Industry

ALD Related products

Thermal Batch ALD

CBATCH 100s Batch Thermal ALD

CBATCH 100s is an atomic layer deposition (ALD) system designed for 4/6-inch LED production lines and oxide layer encapsulation coating on micro/nano-devices fabricated on patterned and planar sapphire substrates.

CBATCH 300s Batch Thermal ALD

CBATCH 300s enables fully automated, high-throughput continuous production, significantly improving throughput and reducing COO (cost of ownership). The system delivers atomic-level precision control, producing pinhole-free, high-quality thin films suitable for high-κ dielectric layers, metal gate deposition, encapsulation coatings, electroplating seed layers, which are widely used in Mini/Micro LED, third-generation semiconductors, and integrated circuit manufacturing.