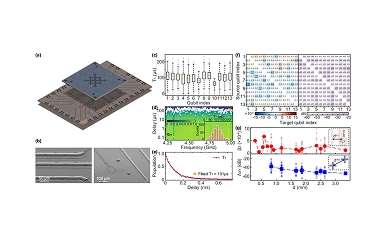

QBT-J Four-chamber Ultra-high Vacuum GLAD System

The system employs linear cascade technology, integrating four chambers for load-lock (pre-treatment) chamber, ion milling chamber, evaporator, oxidation chamber. The fully automated system features simple operation and easy maintenance, utilizing a pick-and-place transfer mechanism to minimize particulate generation. With QBT-J, customers can develop high-quality superconducting devices with broad application prospects across multiple fields.

Wafer Heating: RT-900ºC

Oxidation:Flow and Static Mode Oxidation

Wafer Transfer: Highly reliable and repeatable substrate transferring capability

Wafer Tilt and Rotation: Capable of 180° tilting and 360° rotation with 0.1° precision control

Ebeam Evaporation: UHV 5 Linear Pocket Ebeam Evaporation Source, 8KW Power Supply

UHV Chambers: 4 UHV Chamber, including Loadlock/Aneal, Ion Milling, Ebeam-Evaporation, Oxidation, Ultimate pressure<1E-9Torr

Ion Milling: Kaufman Ion Source, Ion Energy 100-600eV, 100-1200eV, Ion Beam Current: 20-200mA, Etching uniformity <±3% on Ø100 mm substrates