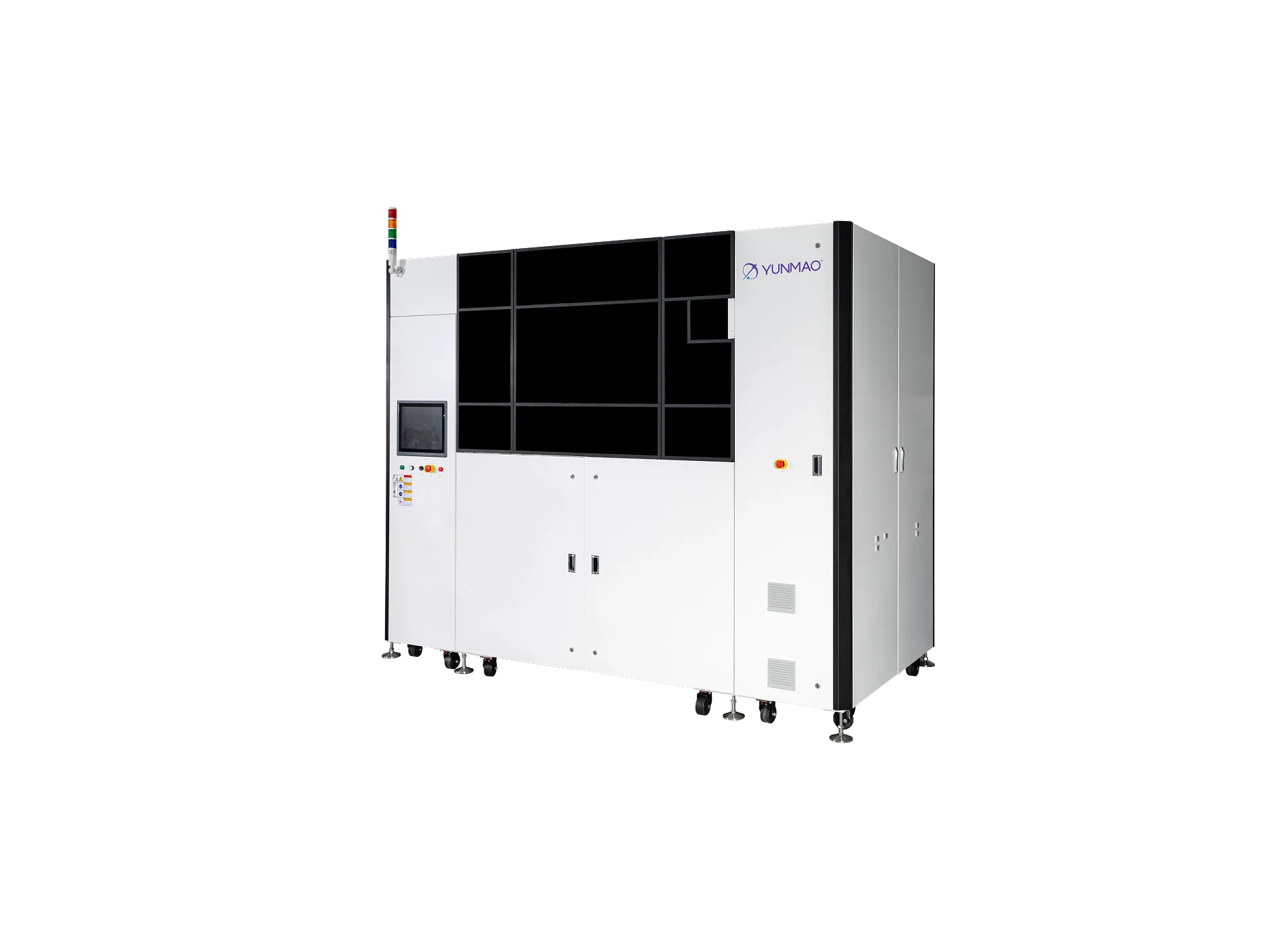

PBATCH Batch PEALD

PBATCH realises low temperature, high quality plasma-enhanced ALD processes for high-quality thin film deposition (e.g., SiO₂, Al₂O₃, TiO₂) on various substrates, including glass, organic materials, polymers, metals, and ceramics. This system delivers exceptional coating uniformity, repeatability, and reliability while achieving industry-leading throughput and yield rates

Sample Size: Up to 12 inch

Fully automated, multi-wafer, high-volume production

Deposits optical films with visible reflectance R<0.05%

Batch-to-batch film thickness non-uniformity of Ru <1%

Industry-leading coating uniformity, repeatability, and reliability

Enables conformal deposition on entire lens surfaces and 3D micro/nano structures

The system enables in-situ plasma cleaning and alternating deposition of multiple thin-film combinations (e.g., SiO₂/Al₂O₃/TiO₂) within a single process chamber.