APPLICATION AREA

yunmao

Frontier Devices

UHV thin film deposition systems provide an ultra-clean deposition environment with a base pressure of 10-9–10-11 Torr, enabling the fabrication of high-quality thin films under precisely controlled conditions. Yunmao UHV equipment platform includes PVD systems and ALD systems widely used in superconducting electronic devices, optical micro/nano-devices, spintronic chips, 3D chip packaging, ferroelectric material-based chips, memory chips and energy storage devices. Yunmao's UHV systems achieve exceptional film uniformity, superior crystallinity and ultra-smooth surface morphology.

Related products

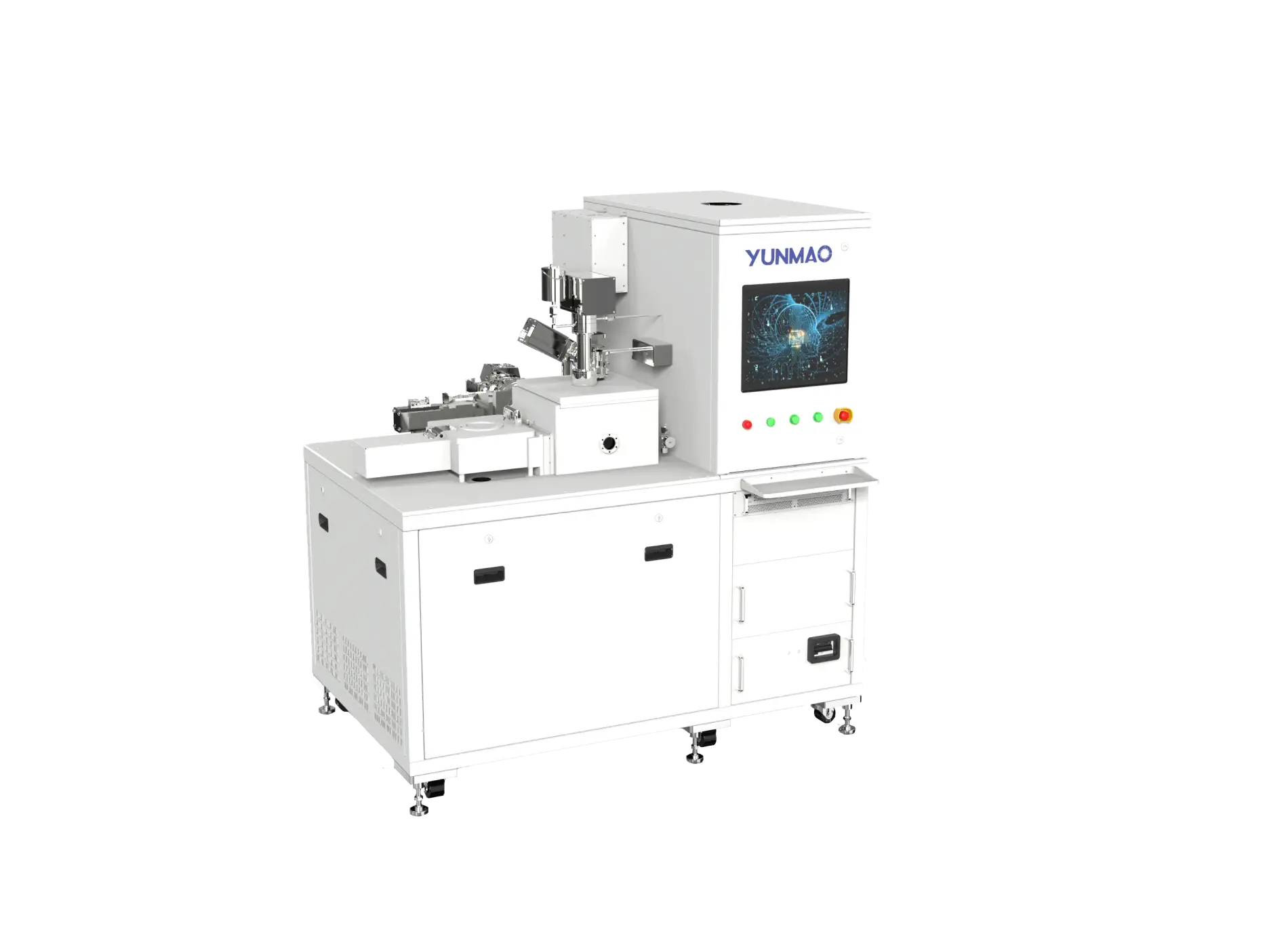

QBT-A High Vacuum Plasma-enhanced ALD System

QBT-A High Vacuum Plasma Enhanced Atomic Layer Deposition System by Yunmao Technology is the first HV-PEALD equipment suitable for high-end R&D and manufacturing in China. It is primarily used for depositing high-quality ALD thin films (oxides, nitrides, metallic elements). Its high-vacuum design reduces system leakage rates and features an oxygen-free ceramic plasma generator, gas passivator, and four dual-tube source bottles. It enables ultra-low RF circuit loss, high-aspect-ratio TSV filling, and ultra-low oxygen content.

QBT-P Dual-chamber Ultra-high Vacuum Magnetron Sputtering System

QBT-P enables high-quality thin-film deposition and can grow high-purity α-phase tantalum films at both high and room temperatures. It deposited α-Ta films exhibit superior superconducting properties with Tc > 4.25 K and residual resistance ratio > 6, enabling low-loss quantum circuits that achieve single-photon Q > 10⁶ and qubit coherence times exceeding 250 μs.

QBT-J Four-chamber Ultra-high Vacuum GLAD System

The system employs linear cascade technology, integrating four chambers for load-lock (pre-treatment) chamber, ion milling chamber, evaporator, oxidation chamber. The fully automated system features simple operation and easy maintenance, utilizing a pick-and-place transfer mechanism to minimize particulate generation. With QBT-J, customers can develop high-quality superconducting devices with broad application prospects across multiple fields.

QBT-MP·L3 Multi-chamber Ultra-high Vacuum Magnetron Sputtering System

Fabrication of superconducting Ta/TiN/NbN/Al/Nb

QBT-P L3 Triple-chamber Ultra-high Vacuum Magnetron Sputtering System(α-Ta、Nb-Ta)

QBT-P L3 includes three process chambers. Compared to QBT-P, one more sputtering chamber is included enabling multi-layer structures, such as Nb/Al-AlOx/Nb, Al/AlOx/Al, or even α-Ta/TaOx/α-Ta junctions. The system is also compatible with seed layer based process.

QBT-MPV Multi-target Ultra-high Vacuum Magnetron Vertical Sputtering System

QBT-MPV is an upgraded system from QBT-P. Compared to QBT-P, QBT-MPV includes up to 4 magnetron cathodes (upon request) in one sputtering chamber, enabling multi-layer process, such as Nb/Al-AlOx/Nb, Al/AlOx/Al, or even α-Ta/TaOx/α-Ta junctions. The system is also compatible with seed layer based process.

QBT-MPC Multi-target Ultra-high Vacuum Magnetron Co-Sputtering System

QBT-MPC includes two ultra-high vacuum chambers Load lock and Sputtering, equipped with a fully automatic operation. The system is equipped with multiple magnetron cathodes with in-situ tilting for co-sputtering process. QBT-MPC is the state-of-the-art sputtering system of material platform, such as spintronics, topological materials, superconducting materials, etc.